Izici zomkhiqizo

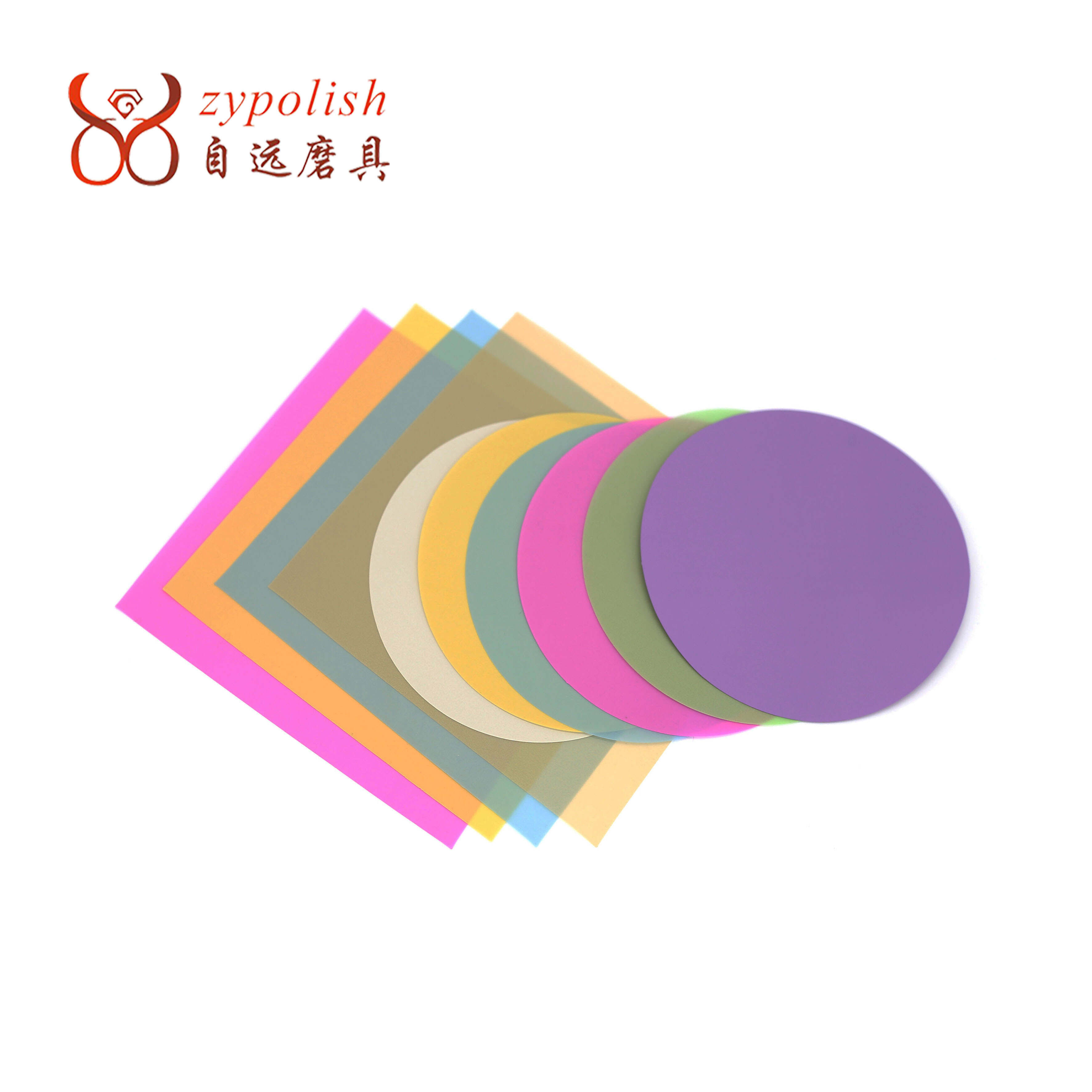

Ukusatshalaliswa okufanayo kwezinhlayiya ezingejwayelekile

Ifilimu ngalinye lokuphayona lihlanganiswe nezinhlayiya zedayimane ezihlakazekile ngokulinganayo, iqinisekisa isenzo sokusika esingaguquki kanye nokuqedwa komhlaba okuphezulu ngaphandle kokuqhekeka noma imigodi.

Amandla ahlukile nokuvumelana nezimo

Yakhelwe ngesisekelo esiqinile kodwa esiguquguqukayo, le filimu yokuphola ivumelanisa kahle ukuhlukahlukahlukahlukana bobunjwa, kusekela imisebenzi yokuphoqelela yemanyundini nangomshini.

Ukunemba okuphezulu okuphezulu kwezicelo ze-optical

Ilungele izidingo ezifunwayo ze-fiber Optics kanye ne-optical lens polishing, ifilimu inikezela ngokunemba okuqediwe okuphakathi kwe-micron kanye nokufana.

Ukuvumelana kwe-batch-to-batch

Ukulawulwa kokukhiqiza okuthuthukile kuqinisekisa ikhwalithi yomkhiqizo ezinzile ngokuhlukahluka okuncane kokusebenza, ukusekela ukukhiqizwa kwesisindo ngaphandle kwekhwalithi yokuyekethisa.

Ukusetshenziswa okumanzi okuhlukahlukene noma okulomile

Ihambisana ne-Dry, Amanzi, noma i-Oid-based Polishing, ihlangabezana nezidingo ezahlukahlukene zezimboni ezahlukahlukene kufaka phakathi ama-Optical, Electronic, kanye Nezindawo Zokuqeda.

Amapharamitha Womkhiqizo

| Ipharameter |

Ukucacisa |

| Igama lomkhiqizo |

Ifilimu yedayimane polishing |

| Osayizi be-grit abahlukumezayo |

30 / 9/1 / 3/ / 1 / 0,,,5 / 0.05 micron |

| Ububanzi be-disc |

Φ 12127mm (5 inch), φ03mm (8 inch), njll. |

| Osayizi beshidi |

I-114mm × 114mm, 152mm × 152mm (6 inch), njll. |

| Ukujiya |

75 micron |

| Isisekelo sezinto |

Ifilimu eliguqukayo |

| Ama-Polishing Medium |

Omile, amanzi, noma uwoyela |

Izinja

Le filimu yokuphambisa isetshenziswa kabanzi embonini edinga ukuqeda indawo enhle, ikakhulukazi:

- Polishing single-core fiber optic izixhumi

- Ukugcona nokuqeda ama-lens abonakalayo, amakristalu, kanye nama-semiconductors

- Ukugaya nokupholisisa ama-roller, shafts, namakhanda kazibuthe

- Ukwelashwa okungaphezulu kwezakhi ze-HDD, amaphaneli we-LED / LCD, kanye nemishanguzo yezimoto

Ukusetshenziswa okunconyiwe

Ukulungiselela ubuso be-fiber optic

Ifinyelela ama-angles aqondile wokusika kanye nokuqedwa okubushelelezi, kubucayi ukuhanjiswa kahle kwesiginali nokulahleka kokufakwa okuphansi.

I-semiconductor surface polishing

Isetshenziselwa ukufeza ukuqeda okuphezulu kwekhwalithi ephezulu kuma-wafers kanye nezinto ezincane ze-microelectronic lapho kubalulekile khona ukuphelela komhlaba.

I-Optical Lens nokuqedwa kwe-crystal

Ihambisa imiphumela enembile yokupholisa kuma-Optical Lens kanye namakristalu abucayi asetshenziswa kumadivayisi wokusebenza aphezulu.

Izingxenye zemishini zikhala

Ilungele izingxenye zokupholisha njengezimoto ezinjengezimoto, amadivayisi wokuqondisa, namakhanda we-HDD ukuthuthukisa ukusebenza nokuqina.

I-Metal Roller Finishing

Iphelele ngokubushelelezi nokuqedela insimbi yensimbi emishini yokuphrinta noma yezimboni lapho kudingeka khona ukubekezelelana ngqo.

Oda manje

Thuthukisa ukunemba nokusebenza kahle kwemisebenzi yakho yokuphamba nge-Diamond Polishing Film Disc-Isixazululo esisebenza kahle samethemba ngaphesheya kwe-stical, semiconductor, kanye nezimboni zemishini. Amasayizi angokwezifiso kanye namazinga we-grit ayatholakala ukuze ahlangabezane nezidingo zakho ezihlukile zokukhiqiza. Xhumana nathi manje ukuthola isilinganiso noma isampula. Uzakwethu nathi ngekhwalithi engaguquki kanye nokusekelwa kwesazi kuzo zonke izidingo zakho zokuphamba.